Precision You Can Trust, Delivery You Can Count On

Client Portfolio

Our Business

Parts Feeding and Handling

With over three decades of technical expertise, SSH Automation is equipped to handle diverse parts feeding projects. Our robust and reliable bowl feeders ensure a steady, accurate flow of components, bolstered by our wide selection of linear feeders, hopper elevator systems, and centrifugal feeders. As the official reseller of Hanshin, a comprehensive standard equipment provider, we're confident in our ability to devise solutions that precisely meet your needs.

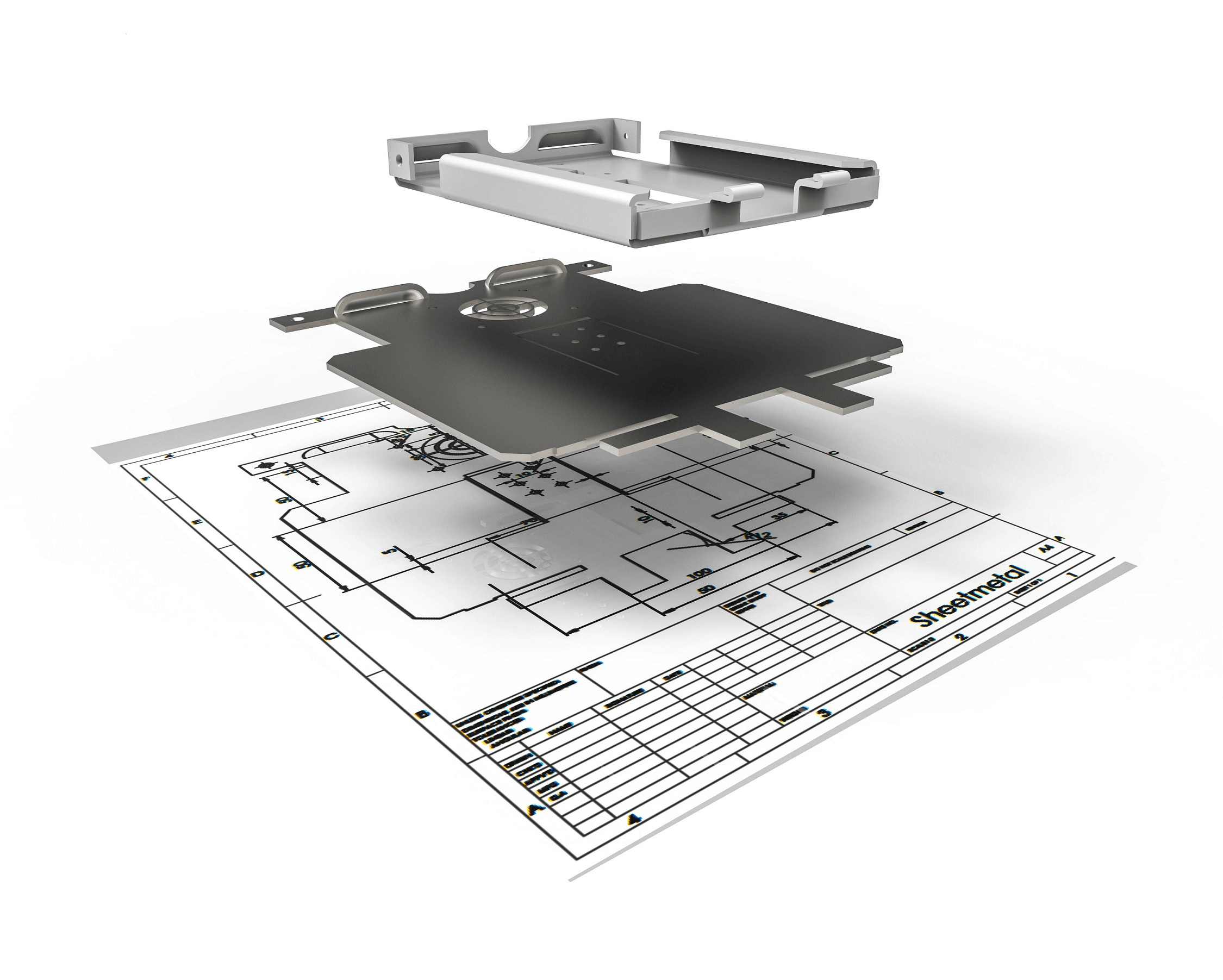

Sheet Metal Fabrication

Boasting a comprehensive suite of metal fabrication equipment, we offer services including CNC laser cutting, CNC bending, CNC milling, and welding. Our capabilities extend to fabricating a variety of items such as brackets, panels, covers, trays, trolleys, and racks using materials like stainless steel (SS304, SS316), mild steel (SS400, S275JR), and aluminium (AL5052, AL6061). We aim to deliver a complete solution for all your metalworking and sheet metal fabrication needs.

Sales & Distribution

As the exclusive distributor of Hanshin bowl feeders, linear feeders, controllers, and cam indexers in Singapore, Malaysia, and Indonesia, SSH Automation leverages extensive knowledge to suggest solutions best suited to your automation needs. We ensure a robust inventory for immediate availability to our regional customers. Furthermore, we're actively seeking sales representatives and agents to expand our footprint in Southeast Asia.

Why Choose Us?

Quality

Reliable

Technology

Uncover a Perfect Business Synergy with SSH

Tap into our comprehensive suite of automation and metal fabrication services. Let's discuss how we can harmonize our capabilities with your needs for increased productivity.

Case Study of Pharmaceutical Parts Feeder

Solution: SSH Automation worked with our customer to develop a multiple track bowl feeder (increasing the overall feed rate and enabling concurrent processing in later stations) which helps to reduce assembly cycle time. The complete set is accompanied by a table structure, sound-reduction enclosure, hopper feeder and linear feeder.

Note: Given the strict manufacturing standards for medical and pharmaceutical products, we collaborated with our customers to ensure all areas of cleanliness and guidance requirements are met.